Amazon FBA Inbound Shipments Pipeline Template

Keep inbound FBA work visible end to end

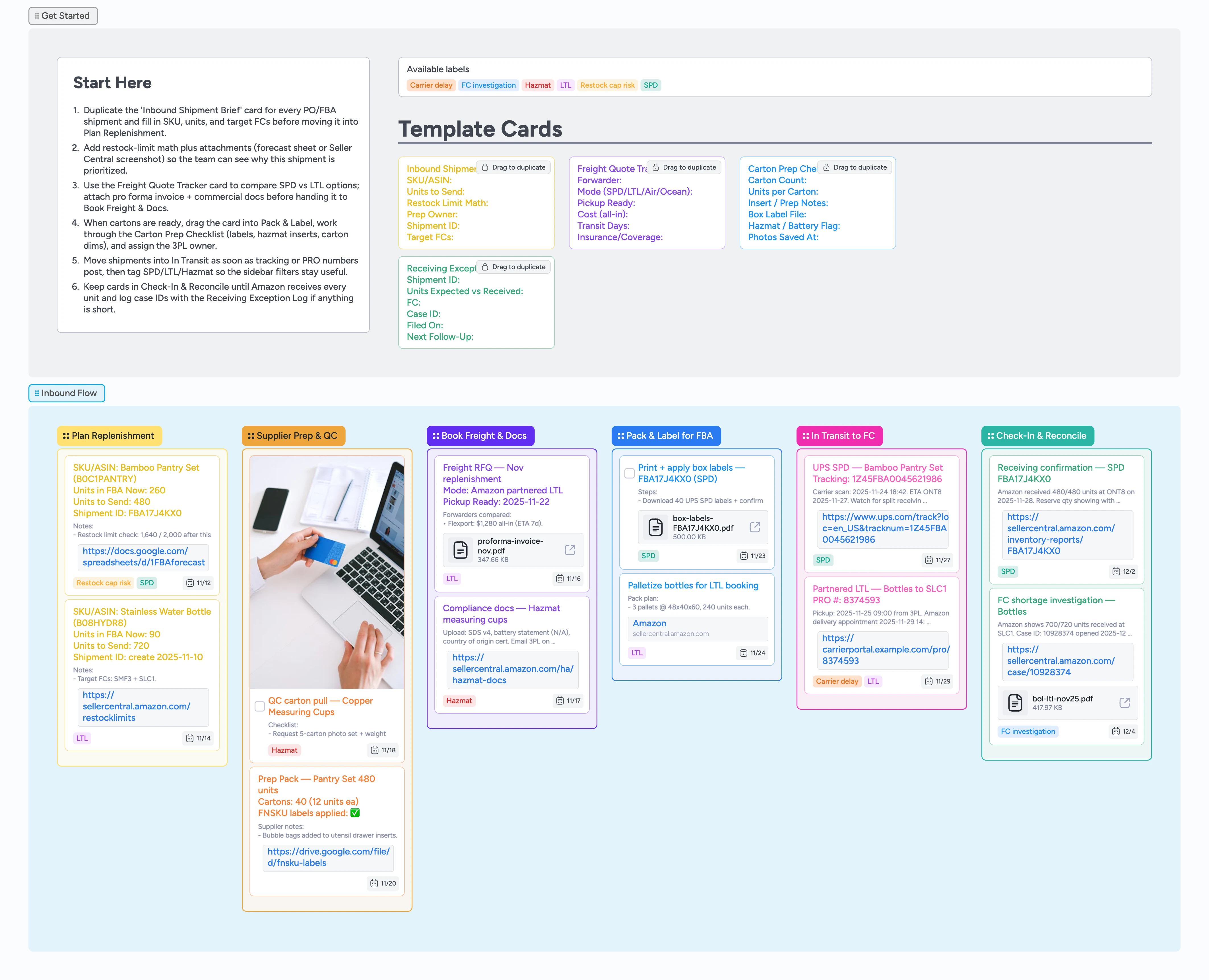

Amazon inbound teams juggle restock limits, SPD vs LTL bookings, prep checks, and FC investigations daily; this template keeps each step tied to one Instaboard card instead of spreadsheets or Slack. Duplicate the Inbound Shipment Brief card, fill SKU/ASIN, shipment ID, attach a forecast screenshot, then drag the card through six stages from Plan Replenishment to Check-In & Reconcile. Locked micro-templates capture freight quotes, carton prep, and receiving exceptions, while labels surface SPD, LTL, Hazmat, carrier delay, and FC investigations. Demo attachments show where to stash invoices, UPS labels, pallet photos, and case IDs so audits take minutes. Click Use Template to open the pre-filled board with locked cards and sample attachments ready to duplicate.

- Drag shipment cards through six Instaboard lanes to see progress instantly

- Attach freight paperwork, QC photos, and UPS labels directly on each card

- Apply SPD, LTL, Hazmat, carrier delay, or investigation labels for filterable queues

- Skip manual data entry—launch new shipments in under a minute by duplicating locked briefs, freight quotes, prep checklists, and exception logs

- End Slack tag hunts—@mention suppliers, 3PLs, or finance on cards so everyone works from the same docs and due dates

Start in Plan Replenishment

Open the Get Started section and duplicate the Inbound Shipment Brief card for every PO you plan to send. Fill the SKU/ASIN, units, restock limit math, shipment ID, and target FCs, then assign the owner who will shepherd it. Attach your forecast spreadsheet or Seller Central screenshot so demand math lives on the card. Apply SPD, LTL, Hazmat, or Restock cap risk labels immediately so filters stay meaningful. Drop a due date tied to the Amazon-ready date before dragging the card into Plan Replenishment.

Pro tip: Keep one card per shipment ID so transit notes stay linear.

Control supplier prep & QC

Inside Supplier Prep & QC, duplicate the Carton Prep Checklist whenever you brief factories or 3PLs. Type carton counts, prep notes, and box-label storage links directly inside the card description, then tag Hazmat if inserts or SDS files are required. Convert QC pulls into task cards, assign your QC lead, and upload photo evidence or weight screenshots so disputes stay on the card. Comment @supplier (or your factory lead) on the card whenever weights don't match and share the link when Amazon or your 3PL asks for proof so the entire thread stays attached with timestamps. Keep FNSKU PDFs, insert artwork, and manifest links in the attachments so nobody hunts through Slack. Move the card forward only after the checklist, photos, and QC sign-off live on the card.

Pro tip: Add carton dims to the description so partnered carriers auto-fill booking forms.

Capture freight quotes and compliance docs

Use the Freight Quote Tracker template inside Book Freight & Docs to compare partnered SPD, partnered LTL, or external forwarders field by field so every quote stays comparable. Fill the forwarder, mode, pickup-ready date, all-in cost, and transit days inside the card, then attach the pro forma invoice or commercial paperwork operations needs. Tag SPD or LTL so downstream owners know which labels to print and which carrier portal to monitor. Add SDS files, pallet configurations, and hazmat approvals as attachments, and assign the logistics owner with a due date tied to the pickup request. When the booking confirms, drop the PRO number or UPS tracking reference into the description before moving to Pack & Label, then sort or filter cards by mode or due date to pick the best option without spreadsheet toggles.

Pro tip: If you split shipments, duplicate the card so each booking keeps its own documents.

Pack, label, and hand off

In Pack & Label for FBA, switch the card to task mode so you can tick off label printing, carton sealing, and photo proof. Use the files you stored earlier to print UPS SPD box labels or pallet labels, then upload the PDFs back to the card for audits. Assign the 3PL team, set the pickup-ready due date, and apply SPD or LTL labels so UPS versus carrier runs are obvious. Snap pallet photos or weigh tickets, add them as attachments, and note that everything lives on the card when carriers or Amazon ask for proof. Once the carrier scans the load, drag the card into In Transit to FC.

Pro tip: Batch print labels by stage so every card in Pack & Label correlates to a specific pickup window.

Track transit and reconcile receiving

In In Transit to FC, paste tracking or PRO links into the card attachments or description and note appointment dates so ops can monitor handoffs. Apply the Carrier delay label anytime scans stall more than a day. Filter that label to triage every stuck shipment in one click instead of digging through carrier emails. When Amazon checks the load in, drag it into Check-In & Reconcile and duplicate the Receiving Exception Log if units are missing. Log the case ID, attach the BOL, and set the follow-up date on the card so finance knows who owes Amazon evidence. Archive the card only after shortages are cleared or the shipment posts to sellable inventory.

Pro tip: Set a due date 72 hours out so Instaboard reminds you to sweep cards that are still in transit.

What’s inside

Restock math primer

Duplicate the Inbound Shipment Brief so restock-limit math, target FCs, and owners stay visible to the whole team in real time before you even create the shipment ID.

Supplier prep workspace

Task-style cards capture carton counts, prep notes, hazmat inserts, and QC photos with FNSKU PDFs attached right on the record.

Freight + compliance desk

Freight Quote Tracker and compliance demos walk you through comparing SPD vs LTL, attaching invoices, SDS files, and approvals inside the card so quotes stay comparable without juggling spreadsheets.

Pack-to-receive conveyor

Pack & Label, In Transit, and Check-In stages mirror the Amazon flow so cards—and their attachments—travel from label printing to FC reconciliation.

Template & label bank

Locked briefs, freight quotes, prep checklists, and exception logs pair with SPD, LTL, Hazmat, carrier delay, and FC investigation labels for fast duplication.

Why this works

- Connects forecasting, prep, freight, transit, and receiving in one visual flow

- Turns SPD vs LTL decisions into tagged, documented cards

- Surfaces compliance blockers early with QC and hazmat checklists

- Captures case IDs, BOLs, and tracking proof right where shortages are resolved

FAQ

What if I only use SPD shipments?

Keep using the same stages—tag cards with SPD, attach UPS tracking, and skip any LTL-specific checklist items so the view still shows restock math through receiving.

Where do commercial invoices or SDS files live?

Attach them to the card inside Book Freight & Docs or the Carton Prep Checklist so every document is one click away for logistics, finance, and your 3PL—no more emailing the same file twice.

Can I monitor restock limits and FC cases here?

Yes—log restock math in Plan Replenishment, apply the Restock cap risk label when you get close, and use the Receiving Exception Log template plus the FC investigation tag for shortage cases, and every stakeholder sees the live status on that card without asking for updates.

How do I handle split shipments from one PO?

Duplicate the original card so each FBA shipment ID keeps its own freight docs, tracking links, and receiving notes without mixing timelines.