Contract Manufacturer Onboarding Pipeline Template

Make every contract manufacturer ramp inspection-ready

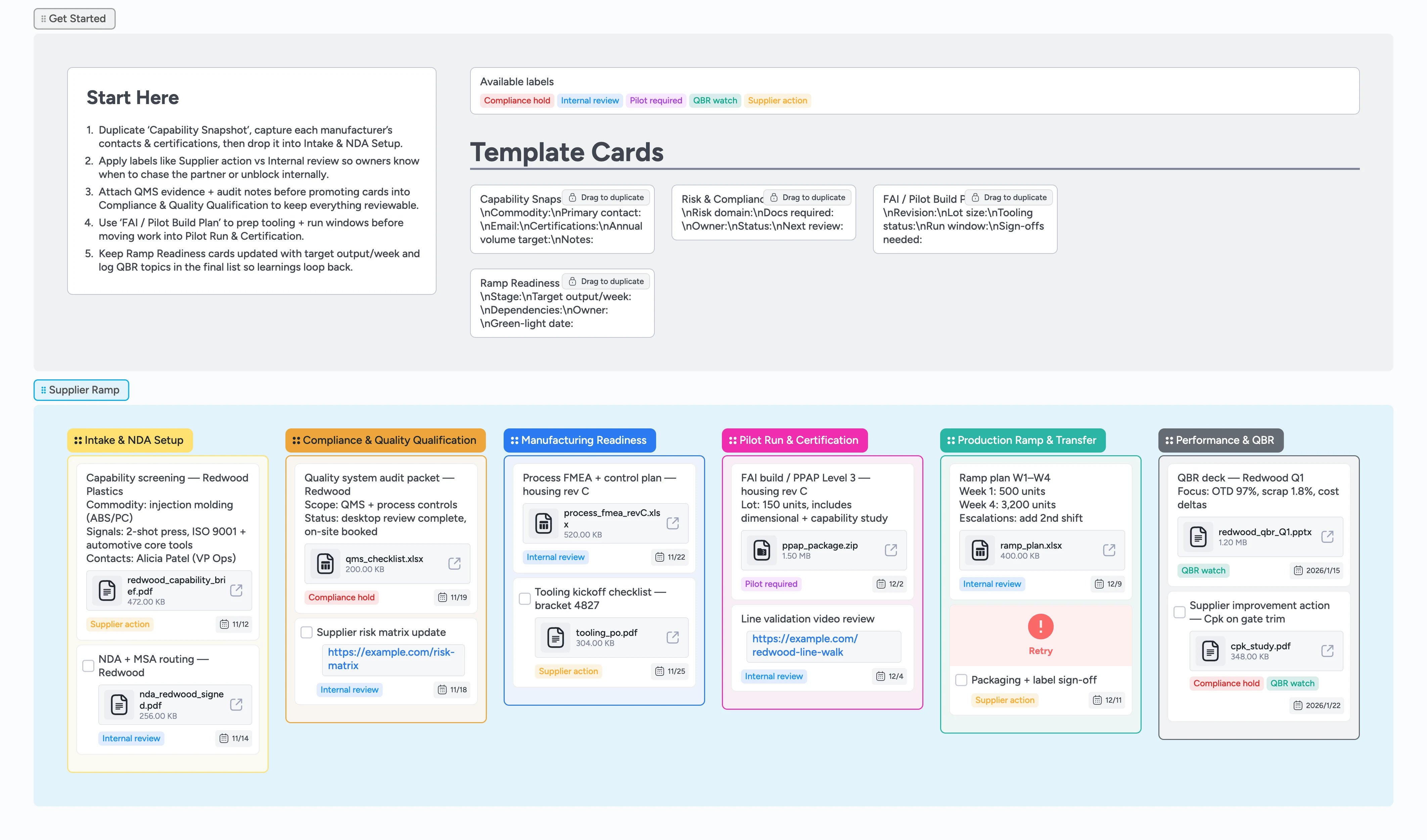

Procurement and operations teams juggle NDAs, quality audits, tooling, and ramp plans across email threads that bury accountability. This Instaboard pipeline keeps each supplier's onboarding journey in one canvas so you can duplicate a micro-template card, assign the right owner, and move it left→right from intake to QBR follow-up. Attach audit packets, PPAP evidence, and ramp spreadsheets directly to the card so nothing gets lost between teams. Labels highlight when you're waiting on the supplier versus an internal review, while due dates and assignees keep every gate on schedule.

- Standardize every onboarding stage with locked micro-template cards from NDA to QBR

- Attach audits, PPAP packets, and ramp plans to cards

- Label supplier versus internal actions for faster handoffs

- Track owners and due dates directly on each column so the ramp stays accountable

Log every manufacturer in Intake & NDA

Start at the Get Started section and duplicate the locked ‘Capability Snapshot’ card. Fill in the commodity, certification stack, primary contacts, and annual volume target, then assign the category lead. Attach any capability decks or scorecards and apply the ‘Supplier action’ label if you're waiting on their paperwork. Once the card is complete, drag it into Intake & NDA Setup and set a due date for the legal packet so reminders kick in.

Collect compliance proof before promoting

In Compliance & Quality Qualification, duplicate ‘Risk & Compliance Intake’ to list every document you need—QMS certificate, insurance, process audit. Assign an internal reviewer, tag ‘Compliance hold’, and add checklist items for each artifact so you can check them off as files arrive. Keep the card in this column until attachments and approvals are done, then move it forward in one drag.

Prove manufacturing readiness

When tooling and PFMEA work begins, drag the card into Manufacturing Readiness and use Instaboard’s task checkboxes to break the work into assignable actions for Quality or the supplier PM. Attach control plans, tooling POs, and measurement data, and use the ‘Internal review’ label to flag who must sign off. Set due dates for each task so Instaboard nudges the team before the pilot window.

Prep and certify the pilot run

Duplicate ‘FAI / Pilot Build Plan’ and immediately attach PPAP packages, capability videos, and study files so reviewers can sign off in place. Then fill in the SKU, revision, lot size, and run window details so the evidence stays tied to the build. Tag the card ‘Pilot required’, assign both the supplier lead and your quality engineer, and convert open items into tasks. When approvals finish, drag the card across Pilot Run & Certification or back to Manufacturing if rework is needed.

Plan ramp and QBR follow-ups

As production starts, duplicate ‘Ramp Readiness Checklist’ to capture weekly output targets, dependencies, and the green-light date. Keep packaging and labeling tasks in the Production Ramp & Transfer column until every checkbox is cleared, then create cards in Performance & QBR for each metric or issue you’ll review. Tag them ‘QBR watch’, attach decks, and assign owners so improvements feed back to the intake lane.

What’s inside

Start-Here intake lane

A guided card shows exactly how to log capability snapshots, contact info, and NDA status before dropping a supplier into the pipeline.

Quality & compliance gate

Locked micro-templates you duplicate in place capture risk domains, required evidence, and review owners while labels show who owes the next action.

Manufacturing readiness checklist

PFMEA, control plan, and tooling cards live in one column with attachments and task checkboxes so engineers approve work without leaving Instaboard.

Pilot run tracker

The Pilot Run & Certification column stores FAI/PPAP cards with embedded videos, measurement files, and approval tasks so every decision lives with the data.

Ramp & QBR lane

Ramp Readiness cards log output targets, packaging sign-offs, and recurring QBR actions with due dates, plus you can filter by the QBR Watch label to prep reviews.

Why this works

- Locks every onboarding deliverable inside Start-Here and duplicateable cards so teams follow the same playbook

- Surfaces compliance blockers via column position, labels, and inline evidence before production begins

- Shows pilot readiness and ramp capacity with task checkboxes, due dates, and attached PPAP files

- Loops QBR learnings back by duplicating cards into Intake with updated checklists and QBR Watch labels

FAQ

Can I adapt the stages for different product families?

Yes—rename or duplicate columns for electronics, plastics, or textiles while keeping the same micro-templates so every supplier still follows the core gates.

How do I keep audits and PPAP evidence easy to find?

Attach PDFs, spreadsheets, or videos directly to the supplier card, then filter by the ‘Compliance hold’ or ‘Pilot required’ labels or use Instaboard search to jump straight to that evidence.

Does this work if one supplier runs multiple SKUs?

Create one card per SKU or program, link them with portals if needed, and apply the ‘QBR watch’ label to any high-risk SKUs for quarterly follow-up.

Can I connect this pipeline to my ERP or PLM tasks?

Link out to ERP work orders or PLM records in the card attachments, duplicate Ramp Readiness cards to mirror those milestones, and set recurring due dates so you update Instaboard at the same weekly cadence as your source system.