Etsy Coasters Made-to-Order Production Template

Keep custom coaster orders curing on time

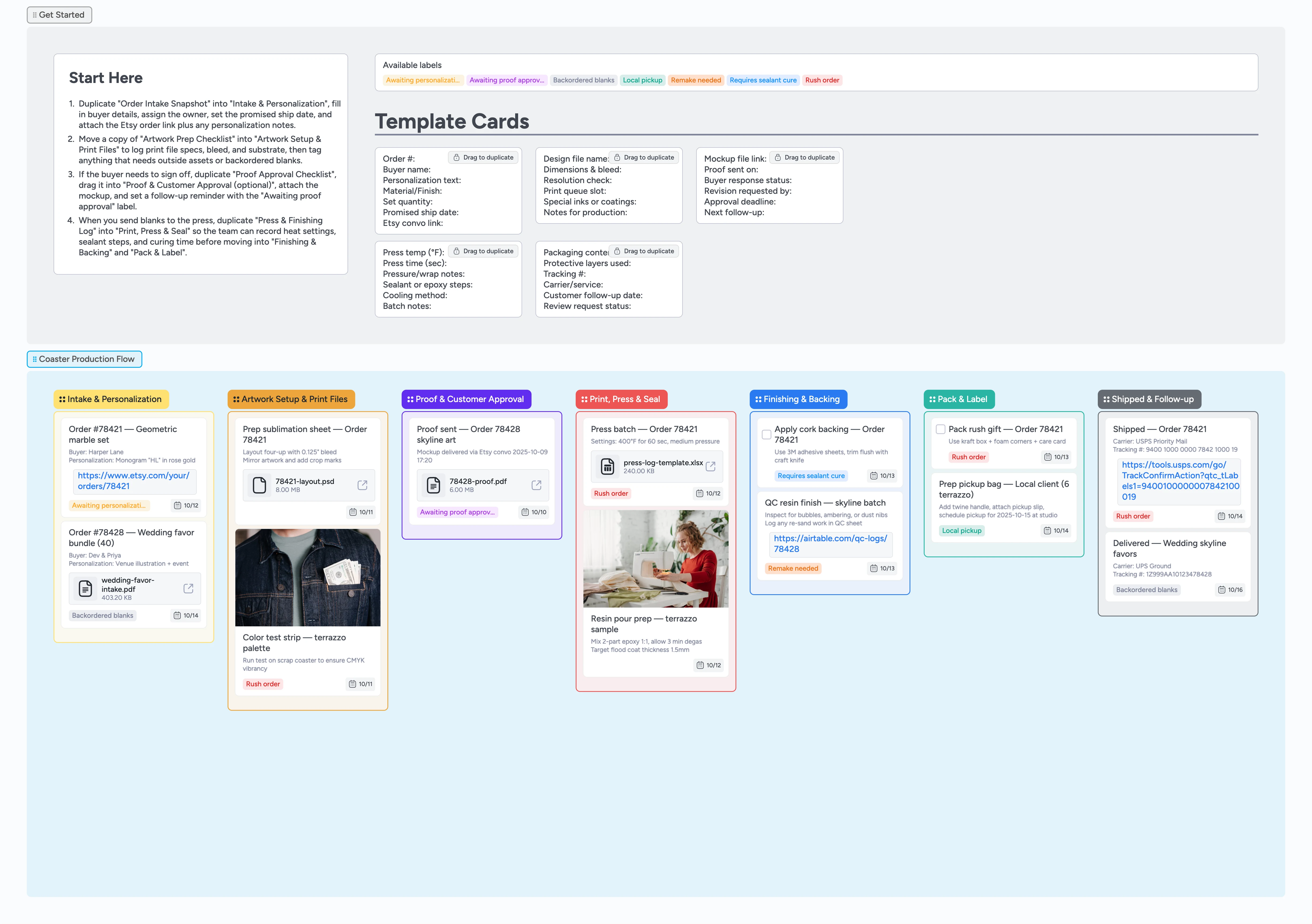

Custom coaster shops juggle buyer text, artwork tweaks, and cure windows across sticky notes and DMs. This Instaboard pipeline keeps the whole flow on one canvas where duplicate-locked cards, labels, and checklists move each order from intake to shipped without guessing which batch is dry. Intake cards capture personalization, optional proof lanes show who owes feedback, and press logs store heat and epoxy steps you can reuse on the next run. Use labels to flag rush orders, sealant cure holds, or local pickups so the whole team knows what needs hands today.

- Capture personalization details without chasing Etsy DMs

- Stay ahead of proofs with labels and due dates

- Log press settings on duplicable cards so the crew reuses what works

- Answer status questions fast because assignments, tracking, and cure timers live on one card

Kick off in Intake & Personalization

On the board, open the Intake & Personalization list and duplicate the locked Order Intake Snapshot card. Fill the order number, buyer name, personalization text, material finish, and set quantity exactly as submitted. Assign the teammate responsible, set the promised ship date, and attach the Etsy order link so messages stay one click away. Add labels like Rush order or Awaiting personalization info before dragging the card to the top of Intake for today’s work.

Pro tip: Apply the Backordered blanks label as soon as blanks slip so you can renegotiate delivery dates early.

Prep artwork and print files

When details are locked, move the card into Artwork Setup & Print Files and duplicate the Artwork Prep Checklist. Attach your PSD or SVG, note bleed and mirror settings, and log the print queue slot so the next shift knows where to pick up. Indent the checklist under the main order card so art assets travel with the job, and use the description for color test notes. Tag Rush order if you need to bump the job ahead.

Pro tip: Drop a quick image attachment of the latest color test so everyone sees the target finish.

Route proofs for approval

If the customer must sign off, drag the order into Proof & Customer Approval (optional) and duplicate the Proof Approval Checklist. Attach the mockup PDF, record the date you sent it, tag the card Awaiting proof approval, and set a due date for the follow-up reminder. Note any revision requests directly on the card so they travel with the job. Once approved, clear the tag and slide the order into Print, Press & Seal.

Pro tip: Set 24-hour due dates on proofs so you can message buyers before cure windows go stale.

Log press, seal, and backing work

Inside Print, Press & Seal, duplicate the Press & Finishing Log to document temperature, dwell time, tape placement, and cooling method before you start. Add cure time, ventilation reminders, and flip notes to the card description or checklist so future batches reuse them. Move the card into Finishing & Backing once the pieces cure, then record cork or felt application steps and tag Requires sealant cure if the set needs extra drying time.

Pro tip: Keep the Press & Finishing Log pinned under each order so future batches reuse the same settings.

Pack, ship, and follow up

When the set passes QC, drag it into Pack & Label and duplicate the Packaging & Handoff card. List padding layers, inserts, and freebies, then add the tracking number or pickup details before the box closes. Label local customers with Local pickup, assign the teammate handling delivery, and set a follow-up date for review requests. After the carrier scan, move the card into Shipped & Follow-up, attach the tracking link, and leave a reminder note for your thank-you message.

What’s inside

Left-to-right coaster pipeline

Intake & Personalization, Artwork Setup & Print Files, Proof & Customer Approval (optional), Print, Press & Seal, Finishing & Backing, Pack & Label, and Shipped & Follow-up reveal at a glance which orders are waiting on blanks, curing, packed, or shipped.

Order intake starter cards

Duplicate-locked Order Intake Snapshot cards store buyer info, personalization text, material choice, quantities, due dates, and Etsy links so production never digs through messages again.

Artwork & proof workflows

Use the Artwork Prep Checklist for file specs and keep mockups, revision notes, and approvals attached to the same card so handoffs happen inside Instaboard.

Press and seal log

Duplicate the Press & Finishing Log card for every batch to record temperature, time, pressure, epoxy steps, and cooling instructions that stay with the order as it moves.

Labels for production signals

Rush order, Awaiting personalization info, Awaiting proof approval, Requires sealant cure, Backordered blanks, Local pickup, and Remake needed keep blockers obvious.

Why this works

- Moves intake cards forward with all personalization attached for the art team

- Keeps approval waits visible with targeted labels

- Stores press and cure settings on duplicable Instaboard cards so batches stay consistent

- Lets one card carry finishing, packaging, and follow-up as it moves across lists

FAQ

What if a customer approves art during intake?

Skip Proof & Customer Approval for that order—move the card straight from Intake into Print, Press & Seal and delete the proof checklist so the lane stays clear.

How do I track large wholesale batches?

Create a heading card with the event name, indent each sub-order beneath it, and duplicate one Press & Finishing Log for the shared settings so every coaster stays synced.

Can I log sealant cure time?

Yes. Add the cure duration and ventilation steps to the Press & Finishing Log card, then tag the order Requires sealant cure until the timer hits so teammates leave the set untouched.

How do I handle local pickups?

Apply the Local pickup label, record the hand-off window on the Packaging & Handoff card, and keep the order in Pack & Label until the customer signs for it.