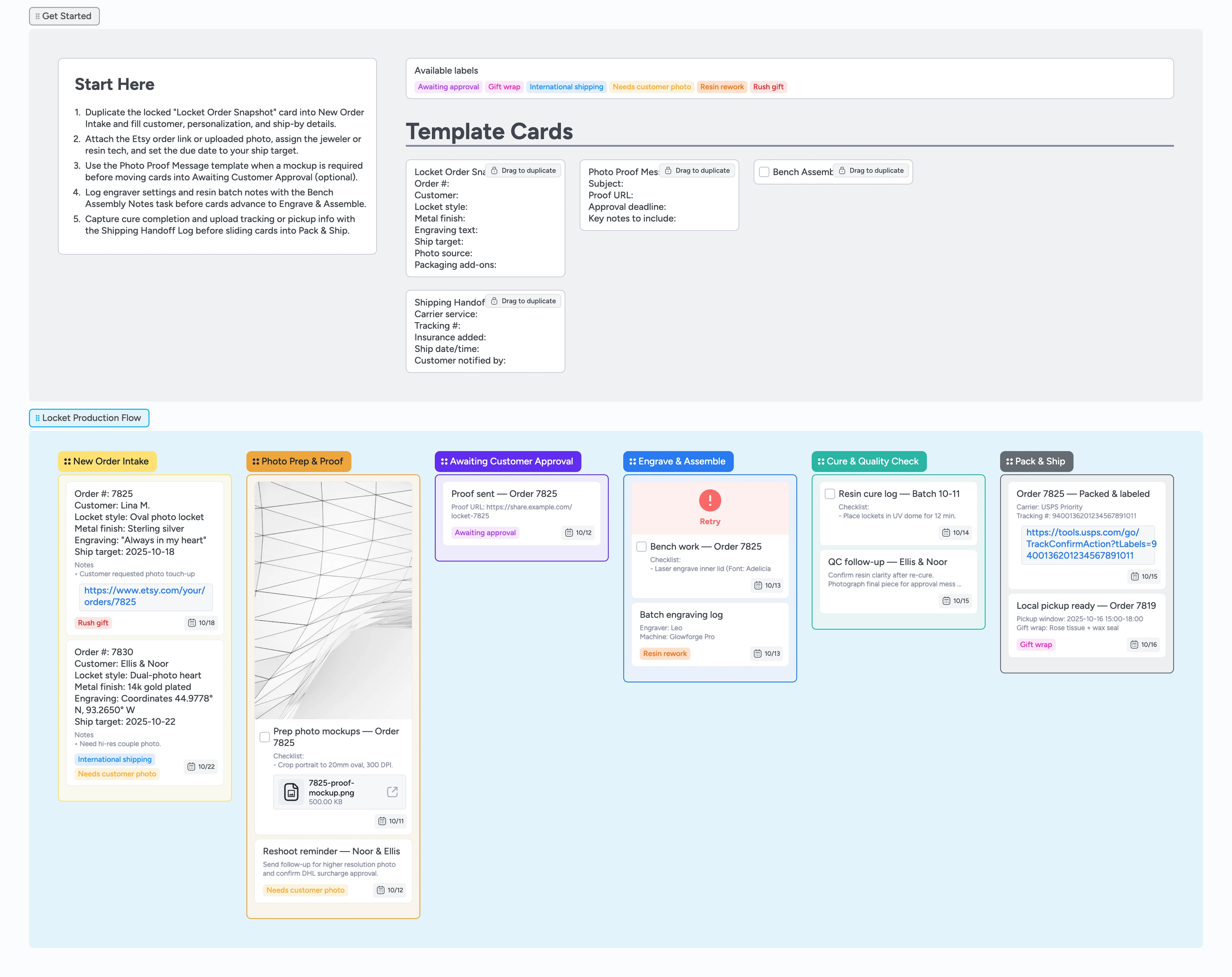

Etsy Lockets Made-to-Order Production Pipeline Template

Run your locket studio from one board

Custom lockets ask you to juggle photo retouching, engraving notes, UV resin cure windows, and carrier drop-offs—often while a customer is refreshing for updates. This Instaboard pipeline keeps every stage in view so you can duplicate a ready-made order card, attach proofs, log engraver settings, and hand off shipping without leaving the canvas. Duplication keeps repeat fields consistent so even a solo maker can move faster with fewer mistakes, while a tiny crew stays aligned from the first Etsy message to the final tracking ping.

- Capture every personalization detail and ship target by duplicating the Locket Order Snapshot card

- Keep photo proofs, approvals, and resin notes attached to each card

- Give your bench team a checklist for engrave and cure steps

- Spot rush gifts and international orders in real time with color-coded labels

Start in New Order Intake

Duplicate the locked "Locket Order Snapshot" card into the New Order Intake list, fill in the customer name, locket style, engraving text, and ship target, then attach the Etsy order link or uploaded photo. Assign the jeweler or resin tech who owns first touch, set the due date to the promised ship-by, and apply labels like Rush gift or Needs customer photo so the team sees urgency at a glance. Move the card right away so nothing waits in your inbox.

Pro tip: Tag rush gifts the moment they arrive so you can batch them into earlier bench slots.

Prep photos and proofs with clarity

When you have the artwork, drag the card into Photo Prep & Proof and duplicate the Photo Proof Message template to draft what you will send. Paste the finalized text and Etsy message link into a card comment, attach cropped PNGs or PSDs directly on the card, and log any color correction notes in the description so bench work sees the edits. Check off the Bench Assembly task steps that apply to mockup prep, and if you are still waiting on a better image, keep the card here with the Needs customer photo label so follow-ups stay visible.

Collect approvals and schedule bench work

If a mockup is required, move the card into Awaiting Customer Approval, paste the proof link, and bump the due date forward so Instaboard pings you when it is time to follow up. When the buyer approves, add their timestamp or message link to the card comment thread and slide the card into Engrave & Assemble. Duplicate the Bench Assembly Notes task to log engraver settings, resin batch numbers, and hinge adjustments, and record any curing time or plating waits in the card description so the next person sees the full context.

Log cure times and quality checks

Advance finished pieces into Cure & Quality Check, then note UV dome start/finish times, resin clarity observations, and hinge tension using the checklist. Attach final photos or quick videos so customer support can share previews, and use the Resin rework label if anything needs another cure cycle. Once QA passes, update the card description with finish notes and move it to Pack & Ship.

Package and share tracking right away

Inside Pack & Ship, duplicate the Shipping Handoff Log to record carrier, insurance, and drop-off time, then upload the tracking link or local pickup instructions. Clear the Rush gift label if timing is confirmed, set a follow-up reminder for customer satisfaction messages, and archive or remove any temporary attachments from the card. Finally, move the card to the far right once the customer has the tracking number in hand.

What’s inside

Locked order snapshot card

Duplicate once to capture customer info, engraving text, packaging add-ons, and the Etsy order link without rebuilding fields.

Photo proof message template

Send consistent approval requests by duplicating the locked card, then pasting the pre-formatted subject line, proof URL, and deadline into a card comment.

Bench assembly task

Log engraver power, resin batch lot, and hinge checks in the card’s checklist so whoever touches the order next sees the latest bench notes.

Cure and QC tracker

Record UV dome times and inspection notes on the card so QA updates travel with the locket as it moves right.

Shipping handoff log

Track carrier choice, insurance, and customer notifications so every keepsake leaves with proof of delivery.

Why this works

- Creates one repeatable intake card you duplicate for every order so every personalization is captured

- Keeps photo proofs, approvals, and bench notes tied to the same card

- Makes resin cure windows visible through due dates, labels, and checklist timestamps

- Guides handoffs from jeweler to shipper with ready-made checklists

FAQ

What if a buyer never sends a high-resolution photo?

Keep the card in Photo Prep & Proof with the Needs customer photo label, log each follow-up in the description, and set a due-date reminder. If you need to cancel, everything you tried is recorded for reference.

How do I track resin cure or plating delays?

Use the Bench Assembly Notes checklist to note the batch mix and curing start time, then add a line in the Cure & Quality Check card description whenever you pause for re-cure or plating.

Can I reuse this flow for lockets made by a production partner?

Yes. Tag the card with International shipping or Resin rework, attach the partner’s production receipt or portal link, and store their promised ship-by date in the due date so your updates stay aligned.

Where do I store customer approvals?

Attach the proof PDF or screenshot to the card and note the approval timestamp in the description or checklist. That history stays with the order even after you archive the card.