Etsy Name Necklaces Production Template

Ship name necklaces without missing details

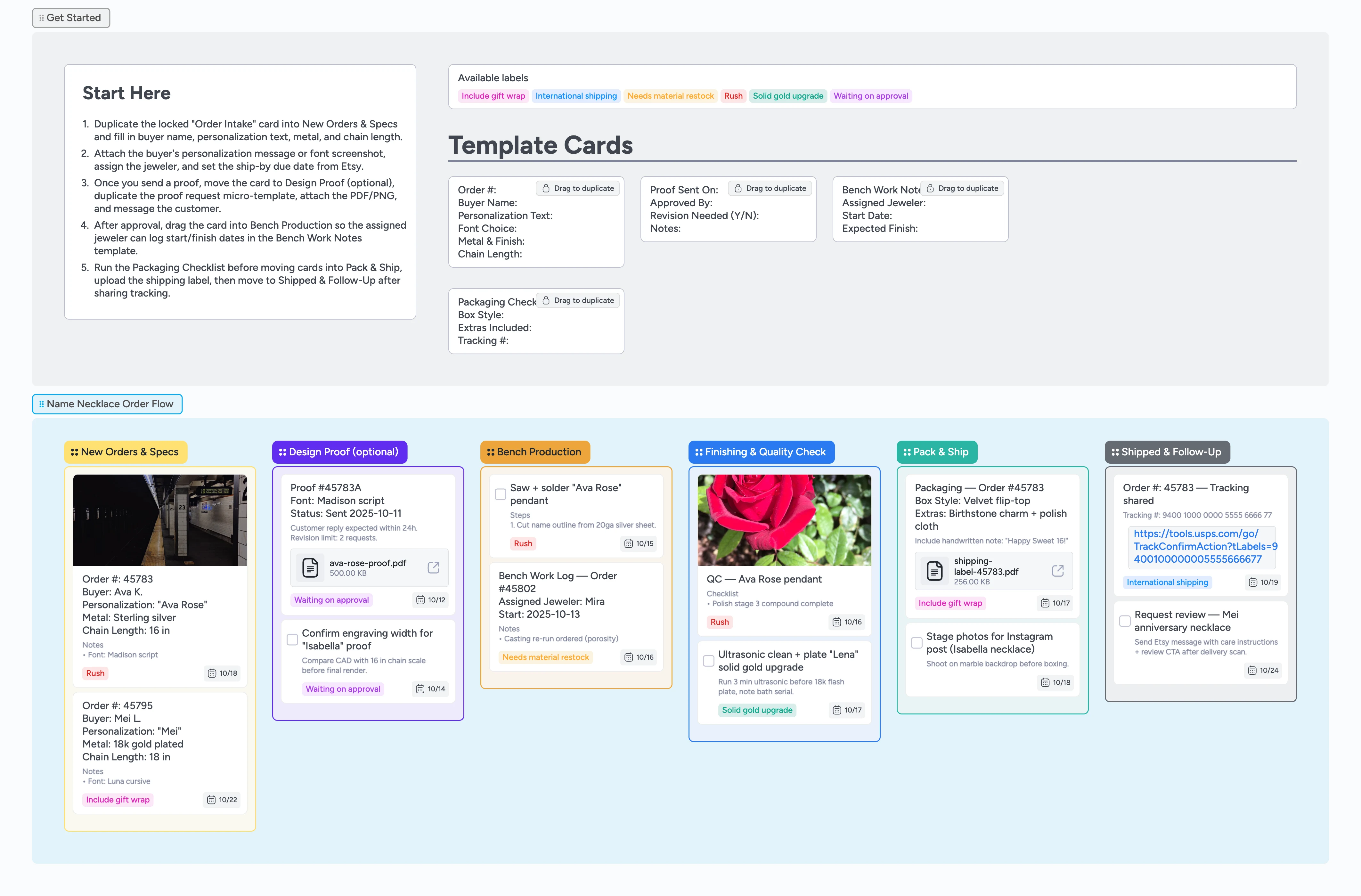

Every personalized name necklace order carries nuanced specs—fonts, metals, chain lengths, promised ship dates. This template keeps them visible from checkout so your team tags Rush orders and never ships the wrong font. Duplicate the intake card to capture personalization, route proofs through a dedicated list, give your bench jeweler (or production partner) a live work log, and keep plating, packaging, and follow-up moving left to right. Instaboard’s duplicate-locked cards, labels, and attachments hold proofs, plating notes, and tracking links in one board your tiny team updates together without digging through messages.

- Prevent wrong name or font errors

- Secure approvals without inbox hunts

- Give bench work live visibility

- Ship faster with tracked follow-ups

Capture specs in New Orders & Specs

Open the New Orders & Specs section and drag the locked "Order Intake" card to duplicate it. Fill each line with the buyer’s name, exact personalization text, chosen font, metal or finish, and chain length pulled from Etsy. Attach the buyer message or font screenshot, assign the jeweler who will start the piece, and set the promised ship-by due date. Apply labels like Rush, Include gift wrap, or International shipping so the queue filters cleanly. Everything lives on the card, giving the rest of the team instant context without Slack pings.

Pro tip: If an order needs materials, add the Needs material restock label before you leave the list.

Route proofs through Design Proof

Move the card into Design Proof once you export a mockup. Duplicate the "Proof Sent On" template, log the send date, approval owner, and any revision notes, then attach the PDF or PNG proof so the bench team sees the exact approved artwork on the same card. Set a follow-up by adjusting the card due date and keep the Waiting on approval label applied until the buyer confirms. When approved, add the final approved-by line and drag the card to Bench Production so production starts with the latest file.

Pro tip: Quick reply templates live in card comments—drop your proof message there so anyone can copy and resend it.

Log work inside Bench Production

In Bench Production, duplicate the "Bench Work Notes" micro-template to record start dates and expected finishes for each pendant. Assign the jeweler responsible, track soldering or casting checkpoints in the description, and leave the Rush label on urgent cards so priorities stay visible to everyone downstream. Because updates stay on the card, the finishing crew and shop owner see status in real time without chasing for a Slack update. Use the checklist to note material pulls or plating prep, and move the card forward as soon as bench work wraps.

Pro tip: Cap this list at three cards—indent extras as a queue so nothing hides off-screen.

Polish and inspect before packing

Drag finished pieces into Finishing & Quality Check and add a quick QC card entry summarizing polishing compounds, plating passes, and inspection results. Attach a photo for fragile or premium upgrades and use the Solid gold upgrade label when you need extra handling so the packer knows exactly which piece they’re boxing. Set the due date to the final ship target so packaging sees what must go out today. Only move forward once QC notes and photos are logged, giving downstream teammates proof the piece passed inspection.

Pro tip: Snap a clean macro photo during QC—it lives on the card for both the packer and the final customer message.

Pack, ship, and follow up

Duplicate the Packaging Checklist template inside Pack & Ship to confirm box style, extras, and branding touches. Upload the shipping label PDF, record the tracking number, and switch the card into Shipped & Follow-Up after the carrier scan. Add a quick note with the message you sent the customer and set a new card due date three days after the delivery scan to trigger your review reminder. Archive Shipped cards weekly so the board stays lean and only active work fills the canvas.

Pro tip: Use the International shipping label to keep customs forms and longer transit timelines in view.

What’s inside

Name necklace order flow

Lists walk each order from New Orders & Specs → Design Proof → Bench Production → Finishing & Quality Check → Pack & Ship → Shipped & Follow-Up so urgent jobs never stall behind routine QC.

Locked intake card

Duplicate-ready card with fields for buyer name, personalization text, font, metal or finish, and chain length so nothing gets missed or mistyped.

Proof handoff kit

Template to record sent and approval dates, attach PDFs or PNGs, and tag waiting approvals so you never start cutting before the buyer confirms.

Production & QC notes

Bench and finishing cards prompt soldering, plating, and inspection checkpoints with space for assignees and due dates, keeping handoffs transparent.

Packaging checklist

Shipping template tracks gift extras, tracking numbers, and customer updates so follow-up happens on time and nothing leaves without a label.

Why this works

- Keep personalization data in one duplicate-locked format

- Surface bottlenecks between proofs, bench work, and finishing

- Attach proofs, plating logs, and tracking in the same card

- Prompt on-time follow-ups that drive reviews and repeat orders

FAQ

What if our shop skips customer proofs?

Archive the Design Proof list or move cards directly from New Orders & Specs to Bench Production—keep the proof template for internal checks if you still want a pre-production review.

How do we track outside production partners?

Assign the card to your partner, note their company in the Bench Work Notes field, and attach any handoff sheets. Use the Waiting on approval or Needs material restock labels to flag dependencies.

Can this handle different metals or finishes?

Yes. Duplicate the intake template for each material choice, or use labels like Solid gold upgrade to surface premium orders. You can also duplicate the whole board for each product line.