Etsy Pint Glass Production Template

Keep every pint glass order on track

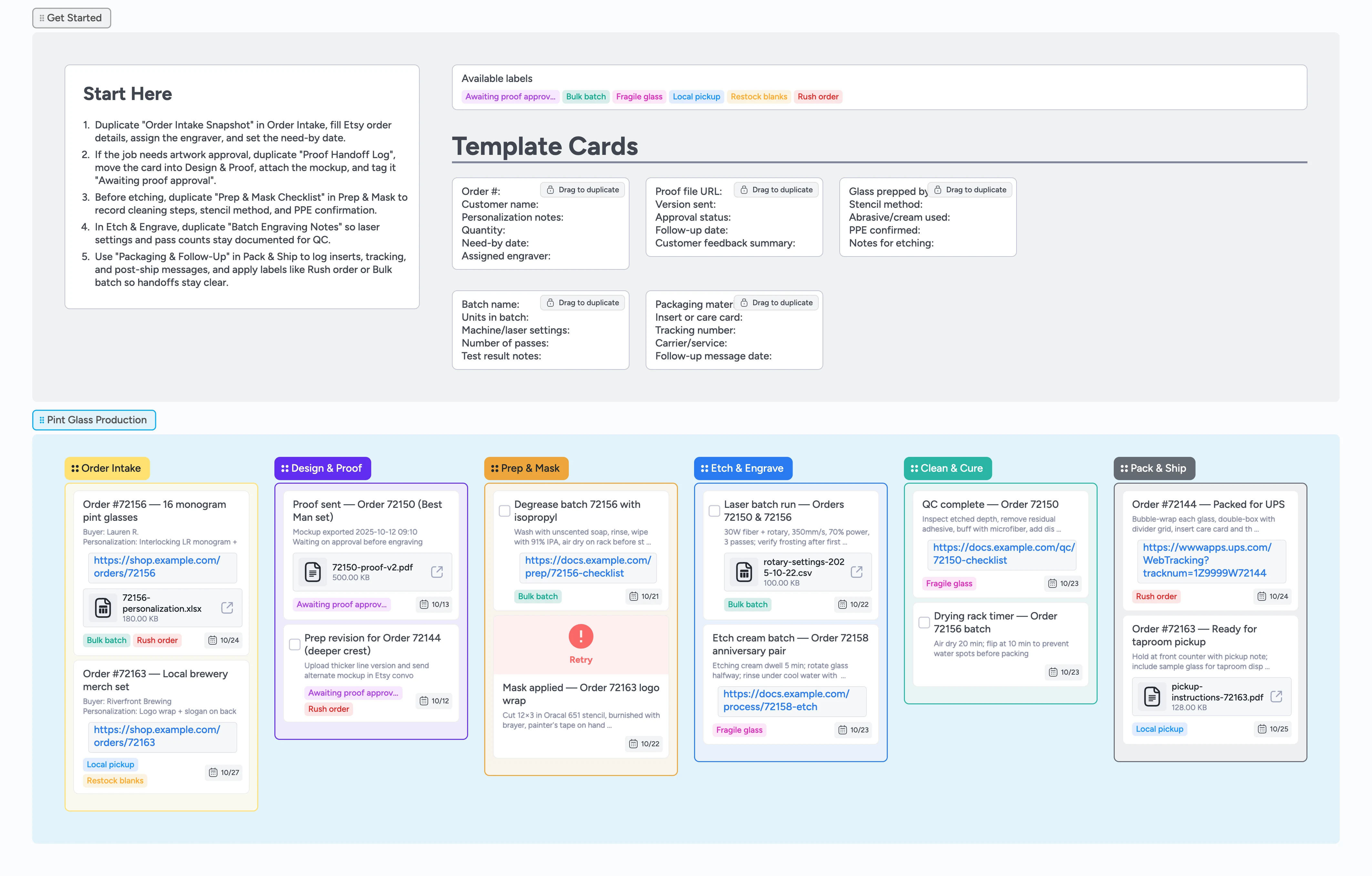

Drag every Etsy pint glass order across one Instaboard canvas so intake, approvals, masking, etching, and shipping stay visible to the whole shop. Duplicate-locked starter cards pull order numbers, personalization notes, and assigned engravers into the board immediately while labels surface rush and proof holds. As you move cards through Design & Proof, Prep & Mask, Etch & Engrave, and Pack & Ship, attachments, comments, and checklists travel with the work so no one hunts through DMs. Log rotary settings, PPE, and follow-up tasks right on the cards to keep busy weeks under control.

- Duplicate intake cards to capture personalization, engraver, and attachments in one place

- Tag proofs and rush jobs so the whole team sees blockers instantly

- Log rotary and cream settings on Batch Engraving Notes to repeat consistent etches

- Duplicate packaging follow-up cards to pair tracking and post-ship outreach

Capture the order in Intake

Open the Get Started section and duplicate the locked Order Intake Snapshot card to capture the new Etsy sale. Fill in the order number, personalization notes, quantity, and assigned engraver, then set the need-by date so production knows the promise. Attach the Etsy receipt or spreadsheet so the source file lives directly on the card for anyone to open. Assign yourself or a teammate and tag the card Rush order or Bulk batch when deadlines or volume need priority. Drop the card at the top of the Order Intake list so today's work stays visible.

Pro tip: Keep only active orders in Intake so urgent jobs never sit below the fold.

Shepherd proofs through approval

When artwork needs sign-off, drag the card into Design & Proof and duplicate the Proof Handoff Log beneath it. Attach the mockup file, note the version you sent, and tag the card Awaiting proof approval so the whole team can see the hold. Add a follow-up date, set a due date, and jot the customer's feedback or requested changes right on the card so proof history travels with it. Because attachments and comments move with the card, Prep & Mask sees the approved layout without reopening email threads. Once the buyer approves, clear the tag, update the status line, and move the card into Prep & Mask for production.

Pro tip: Use card comments for Etsy convo snippets so the exact wording stays with the order.

Prep glassware before etching

Inside Prep & Mask, duplicate the Prep & Mask Checklist and work the tasks from top to bottom. Confirm degreasing, drying time, and stencil method, then record which abrasive or cream you'll use so the next person can pick up midstream. Add any PPE reminders or material holds as notes and attach process docs when needed—assignees watching the card get the update instantly. Keep Bulk batch tags on related cards and indent shared tasks under a heading to highlight group work. Move the order forward only after masks are applied cleanly and surfaces are ready.

Pro tip: Snap a quick photo of masked glass and attach it if the design placement is tricky.

Log every etch setting

In Etch & Engrave, duplicate Batch Engraving Notes for each run so you never guess at rotary or cream settings again. Record machine type, power, speed, number of passes, and dwell time, then attach CSV logs or reference sheets from your controller. Tag cards Bulk batch or Fragile glass when you need a slower tread and note any adjustments the team should repeat. Add assignees so the next shift knows who executed the pass and when to check results. Move the card forward once the etch is complete and the notes are locked in.

Pro tip: Indent smaller companion orders under the main batch card to reuse the documented settings.

Finish, pack, and follow up

After rinsing and QC, drag the order into Clean & Cure and log adhesive removal, buffing, and dishwasher-safe reminders. When it's ready to leave, move the card to Pack & Ship and duplicate Packaging & Follow-Up to document inserts, packing materials, and tracking information. Apply Local pickup for taproom handoffs or keep Rush order if you still owe a delivery confirmation so labels flag the next action. Add the follow-up date you plan to send care instructions or a review request so nothing slips. Archive cards only after tracking is shared and any post-ship notes are resolved.

Pro tip: Store canned pickup messages or review prompts in the card description so they're ready to copy.

What’s inside

Order Intake mini-cards

Duplicate-ready cards for order number, personalization notes, quantity, need-by date, and assigned engraver so nothing enters production incomplete.

Design & Proof lane

Optional stage to log mockups, approval status, follow-up dates, and Awaiting proof approval tags so approvals and files follow the card into production.

Prep & Mask checklist

Task cards capture degreasing steps, stencil method, abrasive choice, and PPE checks with real-time visibility for whoever grabs the next shift.

Etch settings log

Batch Engraving Notes preserve machine settings, pass counts, and attached CSVs or test results so etch history stays tied to each order.

Pack & Ship tracker

Packaging cards collect inserts, tracking, pickup instructions, and follow-up dates so shipping tasks and review reminders live on the same card.

Why this works

- Standardizes intake so personalization stays accurate

- Keeps approvals visible with dedicated Awaiting proof approval tags

- Documents etch settings for consistent engraving quality

- Connects QC, packing, and follow-up in one view

FAQ

What if a repeat customer skips proof approval?

Leave the card in Order Intake, skip the Design & Proof stage, and move straight into Prep & Mask—just note in the template that prior artwork is on file.

How do I block out time for large wholesale batches?

Tag bulk jobs with Bulk batch, assign them to a dedicated engraver, and indent related orders under a heading so shared tasks and settings stay grouped.

Can I log both laser and cream projects here?

Yes. Use the same Batch Engraving Notes card template to record machine, pass count, or cream dwell time and attach reference photos—keep Fragile glass tags on items that need extra care.

How do I track replacements or damaged shipments?

Duplicate the original card back into Order Intake, tag it Rush order, and keep the existing proofs, settings, and attachments so the replacement follows the same documented steps.