Etsy Shot Glasses Production Template

See every shot glass order move together

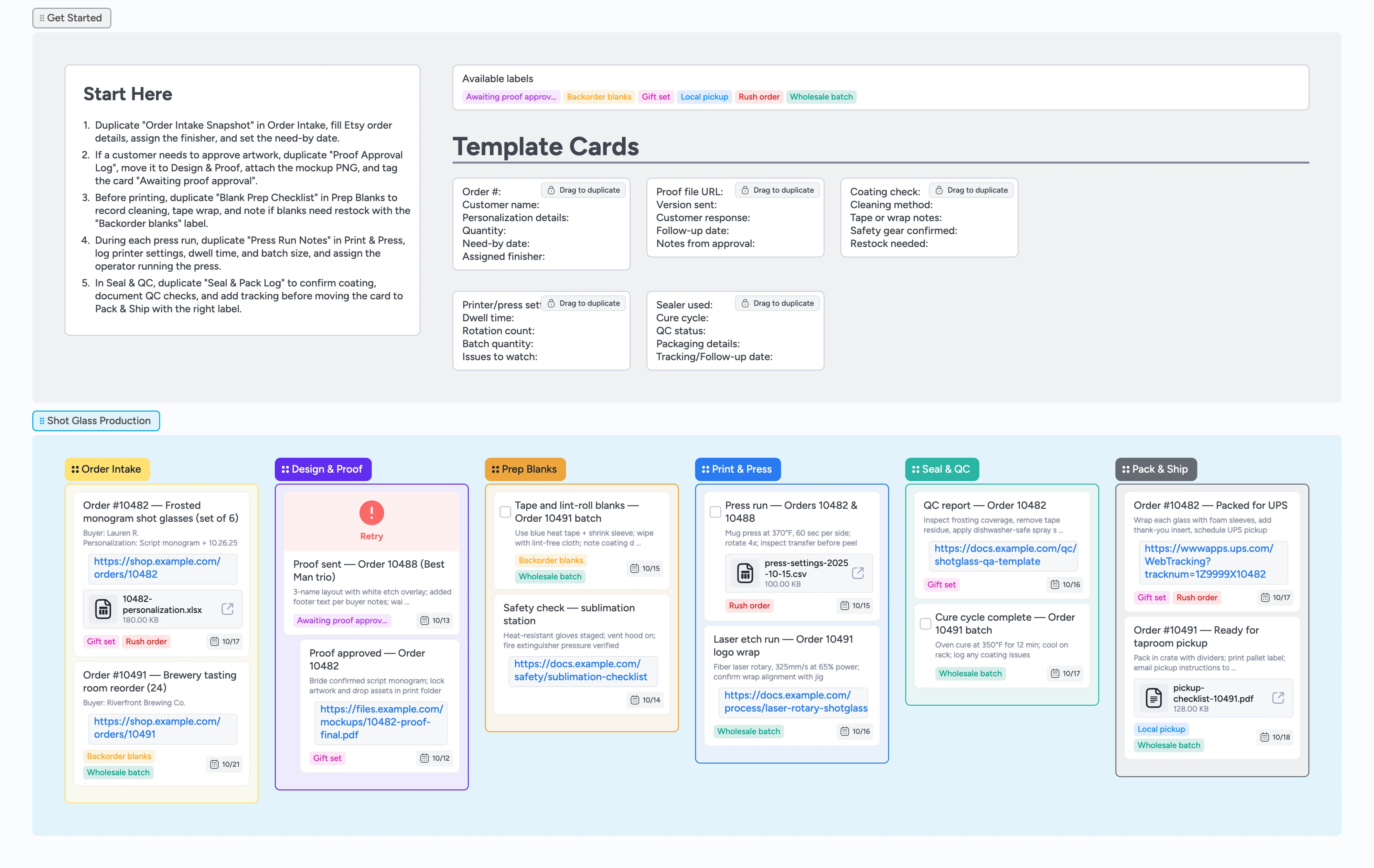

Build one Instaboard that pulls Etsy shot glass work out of buried message threads and into a live production lane. Duplicate-only micro-templates lock the intake fields so nobody accidentally overwrites order numbers, scripts, or assigned finishers as soon as the sale lands. Optional proof lanes carry mockups, approval status, and follow-up dates with tags that spotlight rush jobs or backordered blanks for the whole team. Prep, press, and sealing lists collect batch settings, safety checks, and cure cycles while attachments and comments follow the card down the board. When it's time to ship, packaging, tracking, and thank-you prompts stay on the same card so every handoff happens in real time.

- Duplicate intake cards to capture personalization, assigned finisher, and links instantly

- Tag proofs and holds with Awaiting proof approval or Backorder blanks for fast triage

- Log press settings, attach CSVs, and keep them on the card so repeat batches stay consistent

- Track packing steps, tracking links, and follow-up dates without leaving the board

Capture the Etsy order in Intake

Open the Get Started section, duplicate the Order Intake Snapshot template card, and drop it into the Order Intake list. Fill in the Etsy order number, personalization notes, quantity, and assigned finisher so the card already tells your team who owns the job. Set the due date to the promised ship date and attach the Etsy receipt or spreadsheet for easy reference. Apply labels like Rush order or Gift set so urgent jobs and multi-piece gifts stand out in the lane. With the details set, keep the card at the top of Intake so today's work stays visible.

Pro tip: Store canned personalization snippets in the card description if you reuse phrases.

Route proofs for approval without losing context

When artwork needs feedback, drag the card into Design & Proof and duplicate the Proof Approval Log just beneath it. Attach the PNG or PDF mockup, note the version you sent, and tag the card Awaiting proof approval so everyone sees the hold the moment it happens. Add the follow-up date you promised the buyer, set a due date, and jot their feedback in the notes field so changes stay on the same card your press team will use. Once the buyer signs off, clear the tag, update the response line, and slide the original card into Prep Blanks so the next list owner knows it's ready.

Pro tip: Paste key Etsy convo quotes into card comments so approvals stay searchable.

Prep blanks before running the press

In Prep Blanks, duplicate Blank Prep Checklist to track lint rolling, cleaning, and masking steps for the batch. Log the safety gear you verified, note the tape or shrink sleeve you used, and record whether blanks need reordering with the Backorder blanks label so the restock request is visible. Assign the operator handling prep so the card sits in their assigned queue and they know to pull it forward, and drop any safety reference doc links directly on the card. Indent related tasks under a heading if a wholesale batch requires multiple prep passes. When prep is complete, drag the card into Print & Press so the next stage picks up with full context.

Pro tip: Snap a quick photo of the wrapped jig and attach it when placement is finicky.

Document every press or laser run

Inside Print & Press, duplicate Press Run Notes for each production session so you never guess at heat or laser settings. Log the printer or laser used, dwell time, temperature, rotation count, and batch quantity while the cycle is fresh. Attach CSV logs or process guides and assign the teammate overseeing the run so shift handoffs are painless. Use labels like Wholesale batch or Rush order to signal priorities and point to downstream deadlines. Move the card to Seal & QC once transfers or etches pass inspection.

Pro tip: Indent companion orders under a main batch card to reuse the documented settings.

Seal, QC, and hand off to shipping

In Seal & QC, duplicate the Seal & Pack Log to confirm coating, cure cycles, and quality checks before packaging. Record the sealant used on its dedicated line, note any corrections, and attach QC references so repeat issues are easy to catch. When the order is cleared, drag the card into Pack & Ship, update the packaging details line, and add tracking plus the follow-up date you will send thank-you messages. Apply Local pickup for taproom handoffs or keep Rush order if timing stays tight. Archive the card once tracking is shared and the follow-up is done so the board stays focused on active work while the history remains preserved.

Pro tip: Use card reminders to nudge yourself on review requests after the pickup or delivery.

What’s inside

Order Intake Snapshot

Locked starter card you duplicate inside Order Intake to capture Etsy order number, personalization instructions, quantity, need-by date, and the finisher accountable for delivery.

Proof Approval Log

Optional Design & Proof lane that tracks attached mockup files, customer feedback, and follow-up dates so artwork approvals never stall production.

Blank Prep Checklist

Prep Blanks duplicate card with structured fields for coating checks, lint rolling, tape wrap, and PPE confirmation so every blank is certified before pressing.

Press Run Notes

Print & Press templates document printer settings, dwell time, rotation count, and store attached CSV logs to repeat clean transfers.

Seal & Pack Log

Seal & QC duplicate card that confirms cure cycles, QC status, packaging details, and tracking plus follow-up reminders before you drag it into Pack & Ship.

Why this works

- Standardizes Etsy order intake with assigned owners and due dates

- Keeps mockups, approvals, and follow-ups tied to the same card

- Captures press settings and cure cycles for repeatable production

- Connects QC checks with packaging, tracking, and customer outreach

FAQ

What if a customer skips proof approval?

Leave the card in Order Intake, note that artwork is on file, and move straight to Prep Blanks so production starts without waiting on Design & Proof.

How do I track wholesale or recurring batches?

Tag those orders Wholesale batch, assign the same operator, and indent related run cards under a heading so shared press notes stay grouped.

Can I log both sublimation and laser jobs here?

Yes—use Press Run Notes to capture press temperatures or laser power plus dwell time, and attach the correct process sheet so that same card carries the instructions through QC and shipping for the next operator.

What if blanks are delayed from suppliers?

Keep the card in Order Intake, apply Backorder blanks, and add a due date for the next inventory check so the whole team knows the blocker.