Etsy Tumblers Production Template

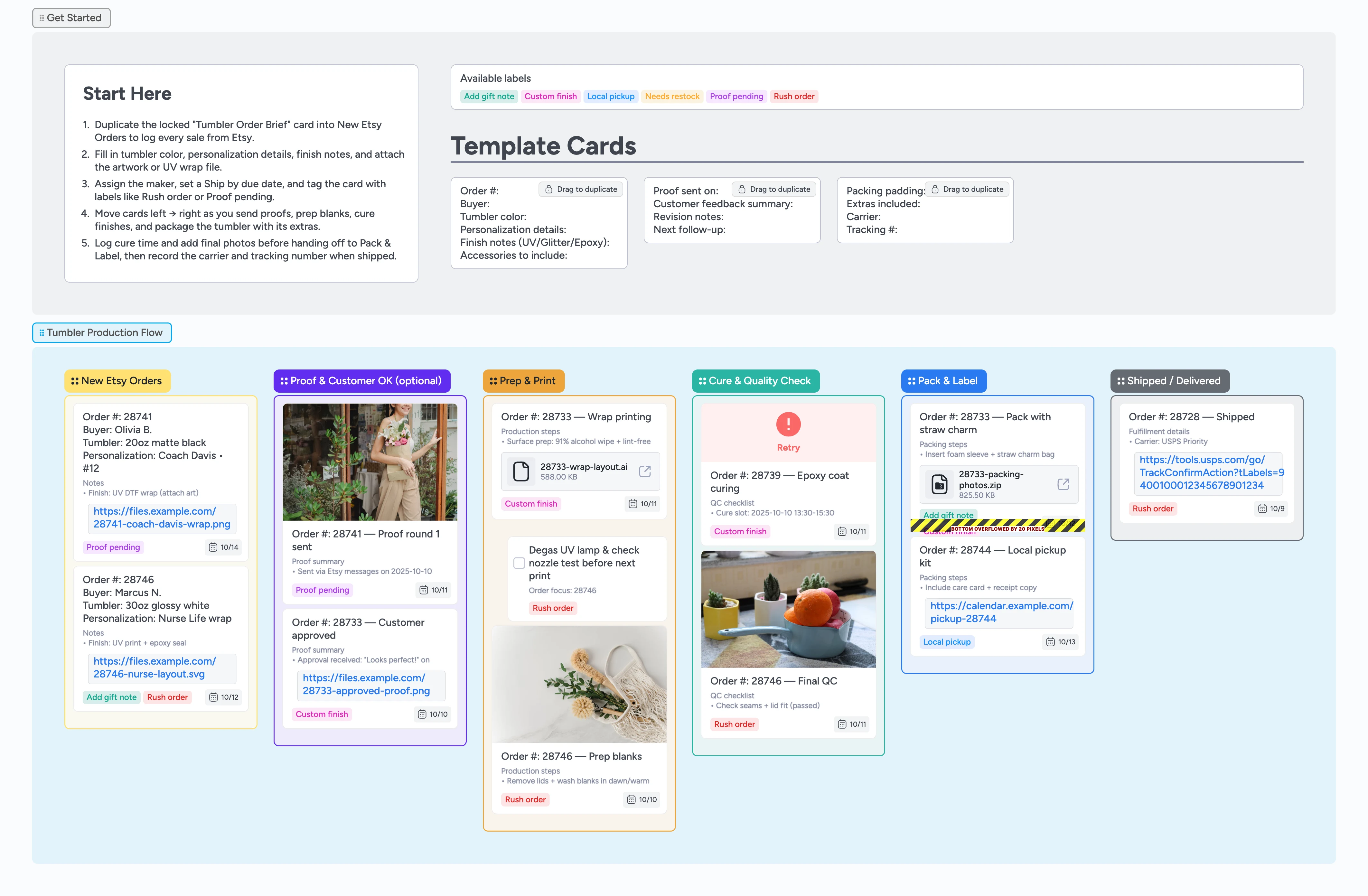

See every tumbler from proof to pack

Custom tumbler shops juggle design approvals, UV or sublimation print settings, epoxy cure windows, and shipping details. Losing the approved artwork file or forgetting whose cup is still curing means frantic Etsy messages and rework. This Instaboard pipeline keeps every order in one view so you can capture personalization, send proofs, log print settings, and hand off packaging without rewriting the same info. Duplicate-locked cards store the order brief, proof follow-up, and packing summary so every maker knows the next action. Labels surface rush jobs, stock checks, custom finishes, or local pickups, and demo cards model how to attach wraps, cure photos, and tracking numbers for fast follow-up.

- See every tumbler stage at a glance

- Lock proof and cure checklists into cards

- Assign makers, comment, and adjust due dates live

- Attach tracking numbers and flag pickups on one card

Log new orders fast

Start in the Get Started section and duplicate the locked “Tumbler Order Brief” card, then drag the new card into the New Etsy Orders list. Fill Order #, buyer, color, personalization, finish notes, and extras exactly as the customer wrote them. Attach the artwork file or UV wrap you downloaded from Etsy so you are using the approved graphics. Assign the maker, set a Ship by due date, and tag rush or pickup requests with the label primer. Done when the Intake card mirrors the Etsy order and is ready to send for proofing or production.

Send and track proofs

If a design approval is needed, move the card to Proof & Customer OK and duplicate the locked proof follow-up card beneath it. Attach the mockup image and add the sent timestamp and message summary so teammates know what the customer saw. Note any requested revisions and bump the due date forward or drop a comment reminder so you follow up within 24 hours. When the customer approves, record who signed off and move the order into Prep & Print so production starts on the latest artwork.

Prep blanks before printing

Inside Prep & Print, confirm blanks are clean, lint-free, and wiped with 91% isopropyl alcohol before applying UV DTF or sublimation designs so coatings bond evenly. Check off each surface-prep step in the card description or checklist and paste the print profile (dpi, lamp power, or press temperature) there so every reprint uses the same recipe. Attach the mirrored wrap or laser file you will run next and drop a comment if the job needs a special jig. If an order needs stock you don’t have, tag it Needs restock and move it back to New Etsy Orders so nothing stalls on the press queue.

Document cure and QC

Drag finished prints into Cure & Quality Check and log cure times, turner slots, and epoxy test results as checklist items or timestamped comments so anyone can see when the tumbler is safe to handle. Add photos of the finish and seams after the wipe-down to confirm there are no bubbles, dents, or missed coatings. If a flaw appears, tag the card Rush order or Custom finish and assign a teammate to rework before the deadline. Move only fully cured, photo-documented tumblers forward so you never seal a soft epoxy or scratched wrap.

Pack with extras

In Pack & Label, duplicate the packaging summary card and list the padding, charms, straws, and care cards you included in the checklist so the person sealing the box can double-check everything. Attach the shipping label PDF or pickup confirmation, add the carrier and tracking number, and snap a quick photo of the packed tumbler for fragile or high-value orders. Use labels to flag Local pickup so you schedule the handoff in the notes, and Add gift note when you tuck in handwritten messages. Once the package is ready, drag the card to Shipped / Delivered.

Follow through after shipping

When a carrier scans the parcel, update the card in Shipped / Delivered with the confirmed ship date and any customer communication you sent. Archive delivered cards weekly so the board keeps attention on active work, and duplicate the packing summary if you need a remake. If a customer reports an issue, duplicate the original card back to New Etsy Orders, tag it Needs restock or Rush order if you are remaking under deadline, and continue the same pipeline to close the loop.

What’s inside

Tumbler production flow

Move cards left to right from New Etsy Orders through Proof, Prep & Print, Cure & Quality Check, Pack & Label, and Shipped / Delivered.

Duplicate-locked briefs

Start each order with a reusable Tumbler Order Brief, proof follow-up log, and packing summary card.

Production checklists

Demo cards show how to record surface prep, UV print profiles, cure windows, and QC notes.

Routing labels

Surface rush, restock, proof pending, custom finish, pickup, or gift-note flags so the right teammate jumps in.

Packaging workspace

Keep foam sleeves, charms, care cards, carrier details, and tracking numbers attached to each order.

Why this works

- Tracks print settings and cure timing where the work happens

- Connects proof approvals to the exact files you produce

- Keeps packaging details and tracking in the same workflow

- Surfaces rush, stock, and pickup flags before they block production

FAQ

What tumbler production methods does this support?

The pipeline works for UV DTF, laser engraving, epoxy glitter, and sublimation because each card captures print settings, cure logs, and reference files.

How do I keep proofs and tracking together?

Attach proof images or PDFs in the Proof list, then add tracking links or label PDFs in Pack & Label so every touchpoint lives on the same card.

Can I skip the proof stage?

Yes. If your designs don’t need approval, delete the Proof list and move cards from New Etsy Orders straight into Prep & Print.

Does this replace Etsy messages?

Keep using Etsy for buyer communication, but mirror the key timestamps and summaries on your Instaboard cards so the production team stays aligned.

How do I hand off an order to another teammate?

Assign the card to the next maker or packer, @mention them in a comment with context, and update the due date so the handoff is visible in real time.