Field Service Dispatch Pipeline Template

Keep dispatch, crews, and billing aligned

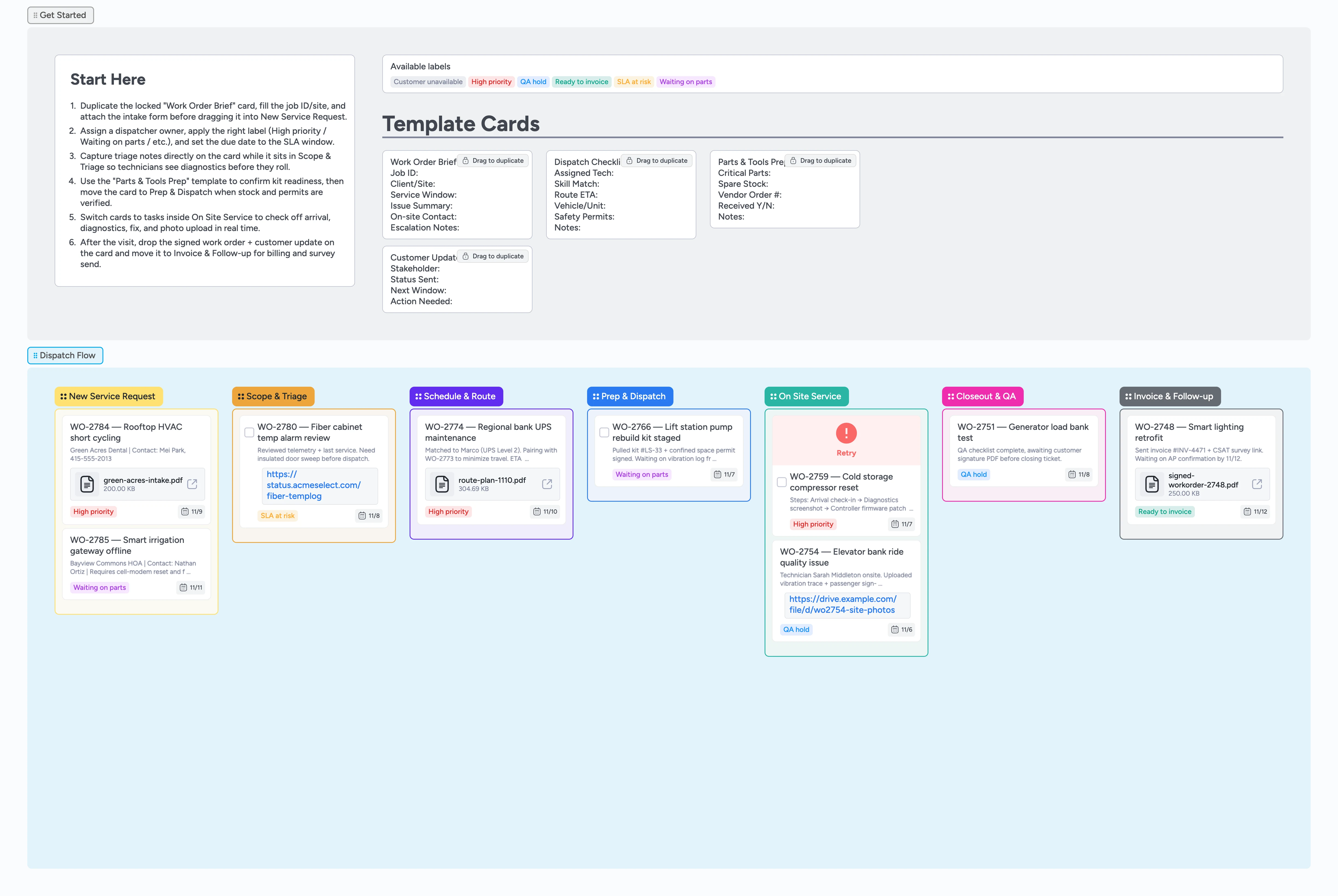

High-priority work orders, weather delays, and parts shortages pile up fast. This Instaboard pipeline captures each request the moment it arrives, locks in triage notes, and exposes routing decisions so technicians, coordinators, and finance stay in the same view. Duplicate the ready-made cards, assign owners, tag risks, and drag jobs left-to-right to show progress. Built-in attachments hold intake PDFs, permits, and photos so you can hand off context instantly and switch from radio calls to a live, collaborative canvas.

- Duplicate Work Order Brief cards so new requests land with clear ownership

- Route qualified jobs using tags, labels, and due dates

- Keep prep checklists, permits, and parts pulls in context

- Give technicians a live space to log progress on site

- Hand finance an invoice-ready queue with audit trails

Log the request in New Service Request

Start at the top-left Get Started section, duplicate the locked "Work Order Brief" card, and drop it into the New Service Request list. Fill the job ID, site, and issue summary, attach the intake PDF or call recording, and assign the dispatcher who owns it. Set the due date to the SLA window so the card immediately shows timing pressure. Apply the correct label (High priority, SLA at risk, Waiting on parts, etc.) before you move on so triage sees urgency at a glance.

Capture diagnostics inside Scope & Triage

Drag the card into Scope & Triage when you have enough context to verify the issue. Use the description field to note telemetry, photos, or firmware versions, and convert the card into a task whenever diagnostics require multi-step verification—check off each confirmation before moving on. Mention technicians in comments to confirm who is best suited, then update the label to SLA at risk if you discover blockers. Once parts, skills, and permits look good, advance the card into Schedule & Route.

Schedule crews and align travel

Inside Schedule & Route, duplicate the "Dispatch Checklist" template to make sure skill match, vehicle, and ETA are documented. Attach exported route plans or shift calendars directly on the card so the field team has everything on mobile. Assign the selected technician, @mention operations for approvals, and drop a reminder in the Customer Update Log so stakeholders know when crews will arrive. If scheduling clears a blocker, swap the label from SLA at risk back to High priority (or remove it entirely) before moving on so the color coding stays accurate. Move the work order to Prep & Dispatch only after parts and safety items check out.

Stage kits and support the field visit

While a card sits in Prep & Dispatch, duplicate the "Parts & Tools Prep" template to confirm inventory, vendor order numbers, and permit status—attach pick tickets or SCADA exports for proof. As soon as the crew rolls, move the job into On Site Service and toggle it to a task card so technicians can check off arrival, diagnostics, fixes, and photo uploads. Require the field lead to add at least one diagnostic photo or note from mobile before you advance the card toward Closeout & QA so downstream teams have evidence.

Close out, QA, and invoice

Shift the work order into Closeout & QA when the visit finishes, then duplicate the Customer Update Log template to capture what was done, who signed, and any follow-up. Apply the QA hold label until inspections and signatures finish, then drag the card into Invoice & Follow-up. Attach the signed work order or invoice PDF, switch the label to Ready to invoice, and @mention finance so they can send billing and surveys without chasing email threads.

Pro tip: Toggle QA hold off and switch the label to Ready to invoice before you leave the board so saved filters instantly show finance which region or crew owns each card.

What’s inside

Start-here dispatch brief

Step-by-step instructions that point you to the Work Order Brief micro-template plus the label primer.

Locked micro-templates

Reusable cards for work order briefs, dispatch checklists, parts prep, and customer updates so teams fill fields consistently.

Seven-stage pipeline

Lists from New Service Request through Invoice & Follow-up mirror the lifecycle of a dispatched job.

Real demo data

Assignees, SLAs, tags, and attachments show how to track HVAC, utilities, and facilities tickets in practice.

QA and billing cues

Labels like QA hold and Ready to invoice highlight who needs to sign off before closing the ticket.

Why this works

- Links triage, routing, and billing into one shared dispatch view

- Provides reusable micro-templates so every work order captures the same critical data

- Highlights risk states with labels so teams swarm the right jobs at the right time

- Keeps customer-facing updates, files, and signatures attached to the live job

- Hands finance a queue of invoice-ready work without exporting spreadsheets

FAQ

Can I manage different service lines in one board?

Yes—use labels such as HVAC, Electrical, or Water to filter, or duplicate the pipeline per division while keeping the same template cards.

How do technicians update cards from the field?

They can open the board on mobile, add photos, toggle task checkboxes, and leave comments so dispatchers see progress instantly.

What if we bill in batches?

Keep cards in Invoice & Follow-up until finance applies the Ready to invoice label, then duplicate the board view as a saved filter for batch exports.

Can we attach compliance documents?

Absolutely—attach permits, safety plans, or signed PDFs directly on the card so QA and auditors can pull them without digging through shared drives.