Inventory Replenishment Pipeline Template

Keep every replenishment cycle aligned

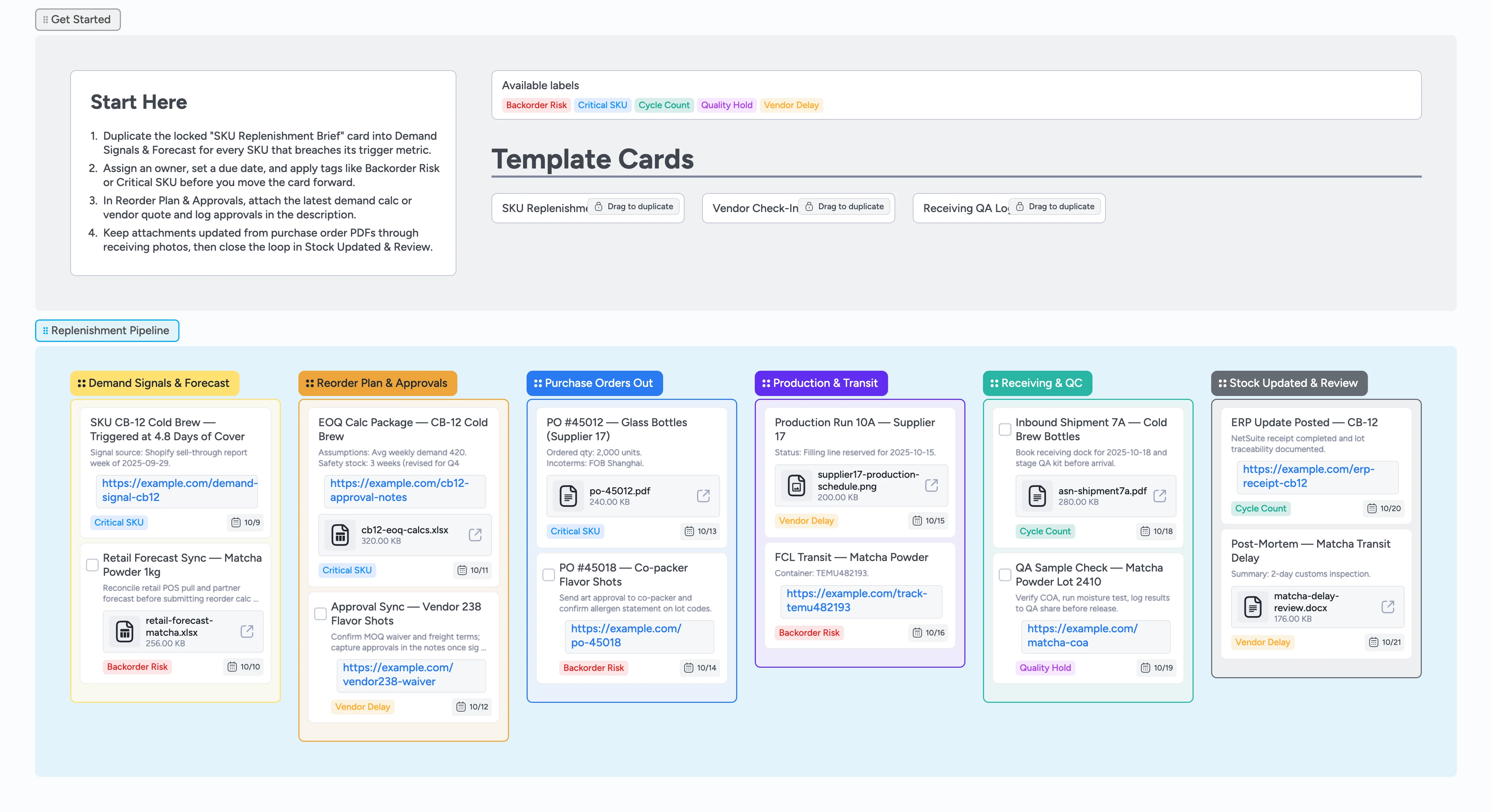

This template lets lean operations teams move from spotting a low-stock alert to updating ERP without chasing spreadsheets. Start in Demand Signals & Forecast to capture why a SKU triggered, who owns the response, and when the next stockout hits. Drag the same card left to right so finance, ops, and CX see purchase order updates, approvals, and attachments in real time instead of trading email threads. Slide that card through production updates, receiving checklists, and final reviews so safety stock tweaks and vendor delays stay visible in one view. With locked briefing cards, ready-made vendor check-in logs, and demo attachments that show what to pin where, you can close the loop faster and protect your fill rate.

- Keep ops, finance, and CX synced on every PO update

- Assign owners and due dates the moment a SKU triggers

- Attach EOQ sheets, PO PDFs, and QA photos to cards

- Surface vendor risks with ready-to-use labels

Kick off in Demand Signals & Forecast

Open the Demand Signals & Forecast list and duplicate the locked SKU Replenishment Brief card for every item under its reorder point. Fill in the SKU, location, trigger metric, and target quantity so the reason for the alert stays obvious. Assign yourself or a teammate and set a due date that matches the latest stockout deadline. Apply the Backorder Risk or Critical SKU label so purchasing knows what to prioritize. Attach the demand report or sales export that triggered the card before you move on.

Pro tip: Sweep this list daily so surprises never pile up.

Build the reorder packet and collect approvals

Drag the card into Reorder Plan & Approvals and document your EOQ or safety stock calculation inside the description. Attach the spreadsheet or quote that backs the quantity so finance can audit without chasing email. Tag the Vendor Delay label if supplier constraints already surfaced and note every approval in the card body. Assign the approver or @mention them to give clear accountability. Once approvals are locked, duplicate the Vendor Check-In Log card so supplier follow-ups start with a consistent outline.

Release the purchase order and track confirmations

Move the card into Purchase Orders Out as soon as the PO is issued. Use the Vendor Check-In Log you duplicated to note deposit status, promised ship windows, and who owes the next update. Attach the PO PDF or portal confirmation link so anyone can reopen documents from the board. Switch labels between Critical SKU and Vendor Delay as status changes to keep stand-ups focused. Update the due date on the card after each vendor touchpoint so transit milestones stay realistic without extra calendar invites.

Monitor production and transit in real time

Advance the card to Production & Transit once the vendor schedules the run or the freight forwarder books space. Add photos, production schedules, or tracking links straight onto the card so ops, finance, and CX share the same live data. Indent supporting tasks beneath the main card to track customs paperwork or packaging updates. Reapply the Vendor Delay or Backorder Risk labels whenever timelines slip so the board highlights exceptions. Keep the Vendor Check-In Log current and adjust the due date to match the latest ETA.

Receive, QA, and close the loop

Drop the card into Receiving & QC when the shipment hits the dock and duplicate the Receiving QA Log template. Record pallets received, inspection results, and any holds, then attach photos or signed delivery paperwork as proof. Assign the warehouse lead to finish checks and tag Cycle Count if reconciliation must happen before release. Once stock is cleared, move the card into Stock Updated & Review, paste ERP receipt references, and schedule the follow-up analysis. Log the takeaways in card comments or duplicate the Vendor Check-In Log for corrective actions before you archive the work so future cycles improve.

Pro tip: Attach QA photos before moving the card forward so finance can approve payments faster.

What’s inside

Demand signal intake

Start Here lane with a duplicate-locked brief to record SKU, location, trigger metric, and owner before work begins.

Reorder analytics lane

Reorder Plan & Approvals column showing sample EOQ math, approvals, and decision notes in context.

Purchase + production tracking

Lists for purchase orders and in-transit updates paired with a duplicate-locked vendor check-in log template and label primer.

Receiving QA toolkit

Receiving & QC lane featuring a locked QA log card and demo attachments that model inspection evidence.

Close-out review

Stock Updated & Review stage to record ERP receipts, run cycle counts, and document post-mortems.

Why this works

- Prevents stockouts by surfacing trigger metrics immediately

- Tracks every vendor commitment alongside purchase orders

- Documents QA evidence and receiving actions in one place

- Closes the loop with ERP updates and post-mortems for each SKU

FAQ

Does this replace our ERP or WMS?

No. Keep your ERP or WMS as the system of record; use this board to coordinate the tasks, documents, and deadlines that keep replenishment on schedule.

How do we handle multiple vendors for one SKU?

Duplicate the card per vendor or indent supporting cards under the primary item, then use the Vendor Check-In Log template to track each supplier’s commitments.

Can we track safety stock reviews here?

Yes. Add review cadence notes inside the card, attach the latest demand model, and tag Cycle Count whenever you recalc buffers so the history stays in line.

What if a shipment arrives partial or damaged?

Stay in Receiving & QC, log the variance in the Receiving QA Log, tag Quality Hold, and keep the card parked until replacements or credits are confirmed.