RMA Returns Pipeline Template

Run every return without losing momentum

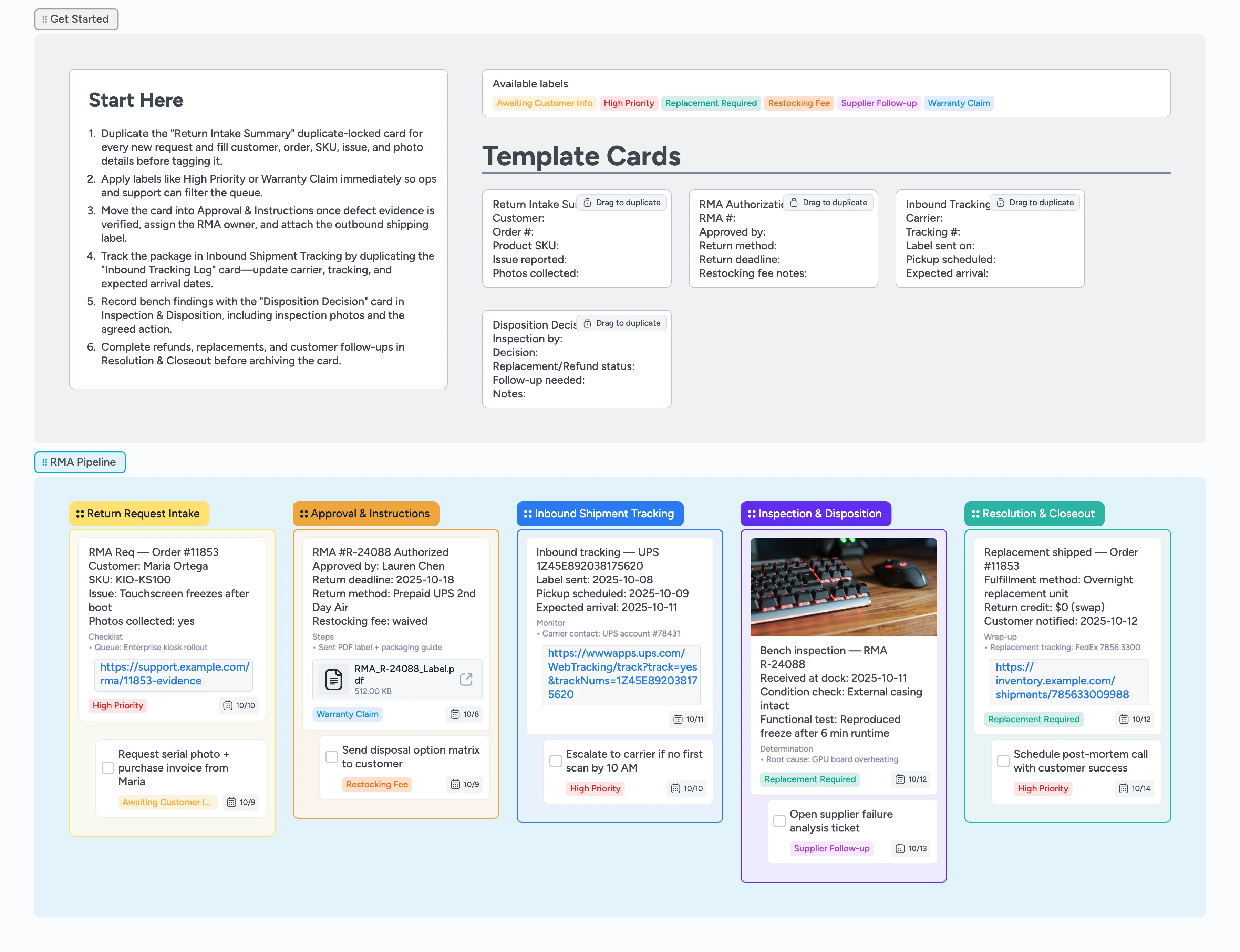

Returns teams stuck triaging inboxes and spreadsheets lose track of deadlines fast. This Instaboard template centralizes intake, authorization, inbound tracking, bench inspection, and customer resolution on one canvas so ops, support, and finance stay synced. Duplicate a pre-filled RMA card, tag it High Priority, and drag it through five columns as status changes. Attach evidence or shipping labels without leaving the board, and keep every task anchored to the card that owns it. When everything from serial numbers to replacement tracking lives in one place, you spot delays early and keep refunds or swap-outs on schedule.

- Standardize every handoff with duplicate-locked RMA cards you drag left to right

- Apply priority labels, due dates, and assignees so owners never miss SLA alerts

- Paste tracking numbers into the card and monitor carrier scans in one view

- Attach inspection photos and disposition notes directly to each case card

- Document refunds or replacements with on-card tasks before you archive

Kick off in Return Request Intake

Open the Return Request Intake list and duplicate the "Return Intake Summary" card for the new case. Fill customer, order, SKU, and issue fields, attach any defect photos, and set a due date before the SLA clock starts. Assign the operations owner immediately so they receive Instaboard alerts as the card moves. Apply labels like High Priority or Awaiting Customer Info to flag what needs fast follow-up. Drag any supporting tasks underneath the main card with an indent to track outreach separately.

Authorize the return and attach instructions

Once the warranty details on the intake card are confirmed, drag the work into Approval & Instructions and duplicate the "RMA Authorization Snapshot" card. Check the confirmation box in the card description, record the RMA number, return method, and deadline, then upload the outbound label PDF. Assign the teammate handling customer communication so they can mark the checklist item when the policy email goes out. Tag Restocking Fee when it applies or note the waiver directly on the card. Track extra tasks such as disposal options as indented subtasks with clear due dates.

Monitor the inbound shipment

Slide the card into Inbound Shipment Tracking once the parcel is on the move and duplicate the "Inbound Tracking Log" card. Capture carrier, tracking number, pickup date, and expected arrival so the whole team can monitor progress without juggling browser tabs. Use the task template to flag escalation if no first scan appears by a set time. Update the card when insurance or declared value changes so finance knows exposure. Keep notifications on so you can nudge the carrier or customer if milestones slip.

Document bench inspection decisions

When the return hits your dock, move the card into Inspection & Disposition and fill the "Disposition Decision" card fields. Log arrival condition, test results, and the chosen action inside the description, then drag in inspection photos so QA sees the evidence. Assign the technician who ran diagnostics so follow-up questions route through Instaboard. Tag Replacement Required or Supplier Follow-up to queue downstream work. Stack vendor ticket tasks under the main card and mark them complete as updates come back.

Close the loop in Resolution & Closeout

Move the card into Resolution & Closeout once you log the refund date or replacement order number in the card. Update the cover card with replacement tracking, credit memo status, and any restocking fees so finance and customer success share the same record. Attach confirmation emails before checking off the follow-up checklist. Assign the teammate running the customer call and add the call date as a comment. Archive only after every tagged task is complete and the card is label-free.

What’s inside

Return Request Intake lane

Duplicate the Return Intake Summary card to capture order numbers, SKU, defect notes, and photo links before anything leaves email.

Authorization toolkit

Record the RMA number on the Authorization card, attach the prepaid label PDF, and check off policy acknowledgement tasks.

Inbound tracking log

Clone the Inbound Tracking Log to store carrier, tracking, insurance, and escalation triggers in a repeatable card.

Bench inspection slate

Fill the Disposition Decision card with root cause, disposition, and supplier tickets while attaching bench photos.

Resolution closeout lane

Log replacement tracking or refund codes on the closeout card and assign finance or success for final confirmation.

Why this works

- Keep ops, support, and finance aligned with real-time Instaboard card updates instead of scattered email threads

- Expose bottlenecks by moving duplicate-locked cards left to right in real time

- Store evidence, labels, and approvals on the case card so audits are painless

- Protect SLAs by pairing due dates with owner assignments at every stage

- Drive follow-through by closing each RMA with built-in tasks and comments

FAQ

Can we track multiple product lines on one board?

Yes. Create labels for each product family (e.g., Hardware A, Hardware B) and filter the board or section by label so engineers and ops view only their SKUs.

How do we handle exchanges that need supplier approval?

Keep the main card in Inspection & Disposition, tag it Supplier Follow-up, and add a subtasks stack with due dates for each vendor ticket so nothing leaves the stage early.

What if we also need credit memo approvals?

Assign the finance approver on the Resolution & Closeout card, attach the memo PDF, and tag Restocking Fee or Replacement Required so controllers see the context.

Does this work for international RMAs?

Move the card to Inbound Tracking, add customs paperwork links and brokerage contacts, and comment with a screenshot when the final clearance scan posts before advancing.